- May 5, 2020

- Jamie

- Facilities, Healthcare, Heat Exchange, Industry, Product Spotlight

- 0 Comments

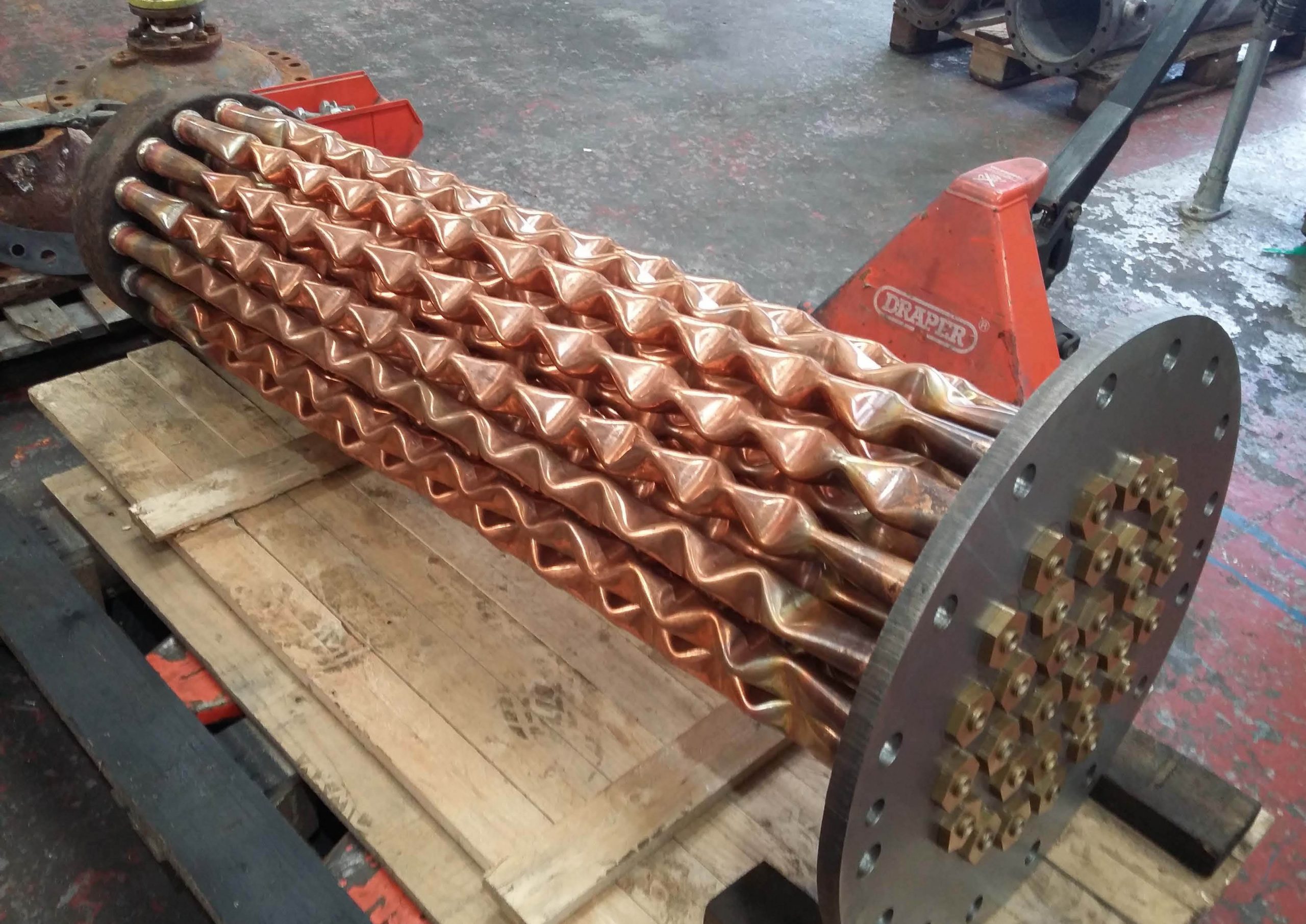

Heat exchangers come in many forms. One of the most common Shell and Tube models we see throughout the UK is a calorifier for managing hot water supply.

Calorifier units are part of an indirect hot water system, supplying hot water for washing or heating throughout a property or facility. For example, we commonly see these units throughout hospitals, industrial production sites, and large buildings.

If this unit is not working, you lose hot water or heating to entire areas of a facility.

Calorifiers are often considered fairly “old” in terms of heating technology, however they tend to have a very long service life, especially when maintained properly on a regular schedule.

Where they have been installed, it is common that this unit has other pieces of permanent plant infrastructure installed around it. This means it would be costly or impractical to remove or replace the calorifier with a different type of system, for example, a Plate Heat Exchanger (PHE) packaged system.

While the ongoing operating costs of a calorifier can be higher than that of a PHE, in an existing system the difference in cost of a replacement system may mean repairing or refurbishing an existing calorifier could be the most cost-efficient option.

Why choose Serck to rebuild or repair your Calorifier?

In our workshops at Serck, we see calorifiers that have been in place for decades that are still in use today. Our team is highly experienced and equipped to return your unit to a like-new condition with work including chemical cleaning, new tubes and tubeplates, as well as pressure-testing and and certification.

If you are deciding whether to repair or replace your existing calorifiers our engineers would be happy to talk through your current setup and the best options for your site. Contact us today.

Recent Comments