Maintaining comfortable ambient indoor temperatures can be extremely resource intensive. Serck are experts in providing products and services to make climate control more efficient and effective. One way to achieve this is by installing heat recovery wheels (also known as rotary heat exchangers).

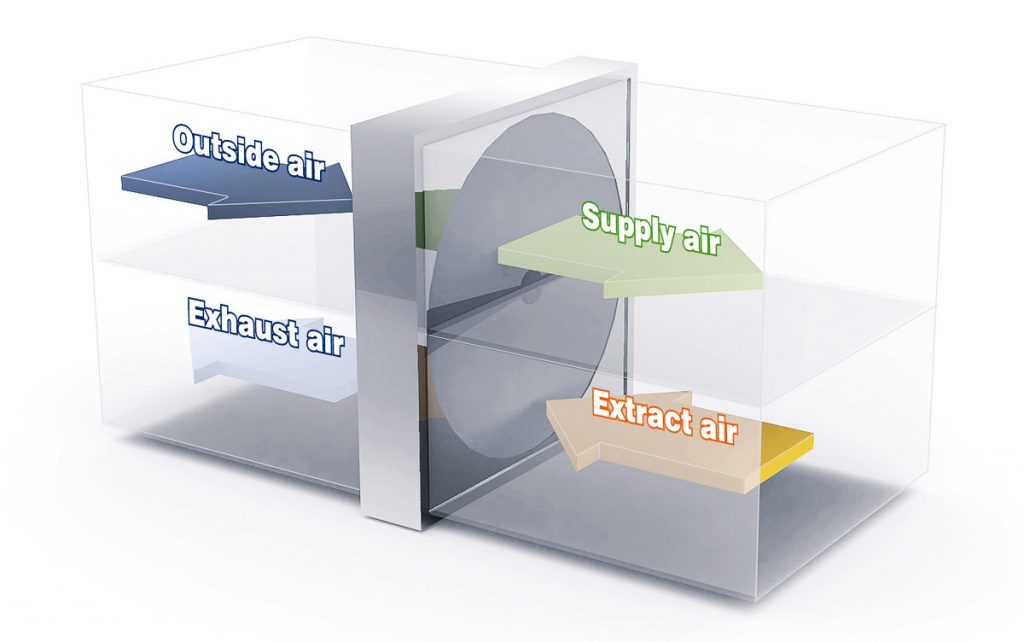

Many HVAC systems require substantial amounts of outside air to be brought in through their ventilation systems. These systems are continually exchanging make-up air (outside fresh air) for contaminated (but cooled) exhaust air. This is an extremely energy-intensive, and therefore expensive, process.

To make these systems more efficient, energy recovery devices, like heat recovery wheels, can be incorporated into the design to transfer some of the outgoing temperature and humidity (energy) to the incoming outdoor air. They are the most effective means of transferring heat; no other device can recover as much heat or cold. And no other heat exchanger can handle such large air volumes.

Rotary-type heat exchangers have a wheel-like construction. This is why they are also known as heat wheels or simply rotors. The rotor, which is constructed like a wheel, consists of an aluminum honeycomb structure within a supporting frame. It rotates nonstop at a slow speed (20RPM) between the stream of hot air and the stream of cold air.

In hot and humid climates, the rotor is cooled in the stream of cold room return air and absorbs the heat from the stream of hot ambient fresh air. Up to 80% of the heat and humidity contained in the air can be recovered in this way.

The Enthalpy type of Wheel, coated with a desiccant material, is rotated between the incoming fresh air and the exhaust air. Heat and moisture are given up to the wheel. In the cooling mode, the incoming air is pre-cooled and dehumidified. When the space is in the heating mode, the heat and desirable humidity is used to precondition the incoming, cold, dry air.

Serck provides EUROVENT certified heat recovery wheels, available in four different standards: aluminum, epoxy coated aluminum, aluminum with a hygroscopic surface and 3A molecular sieve(zeolite) adsorption coating. The width of the wheel rotor is 200mm & the maximum diameter is 6000mm. Epoxy coated aluminum, hygroscopic and adsorption wheels are recommended to rotate 20 rpm. Condensation (aluminum) wheels are recommended to rotate 10 rpm.

Our expert design team would be happy to recommend the solution that would be most optimal for your particular project. If you need help with your HVAC heat recovery projects, contact us today.