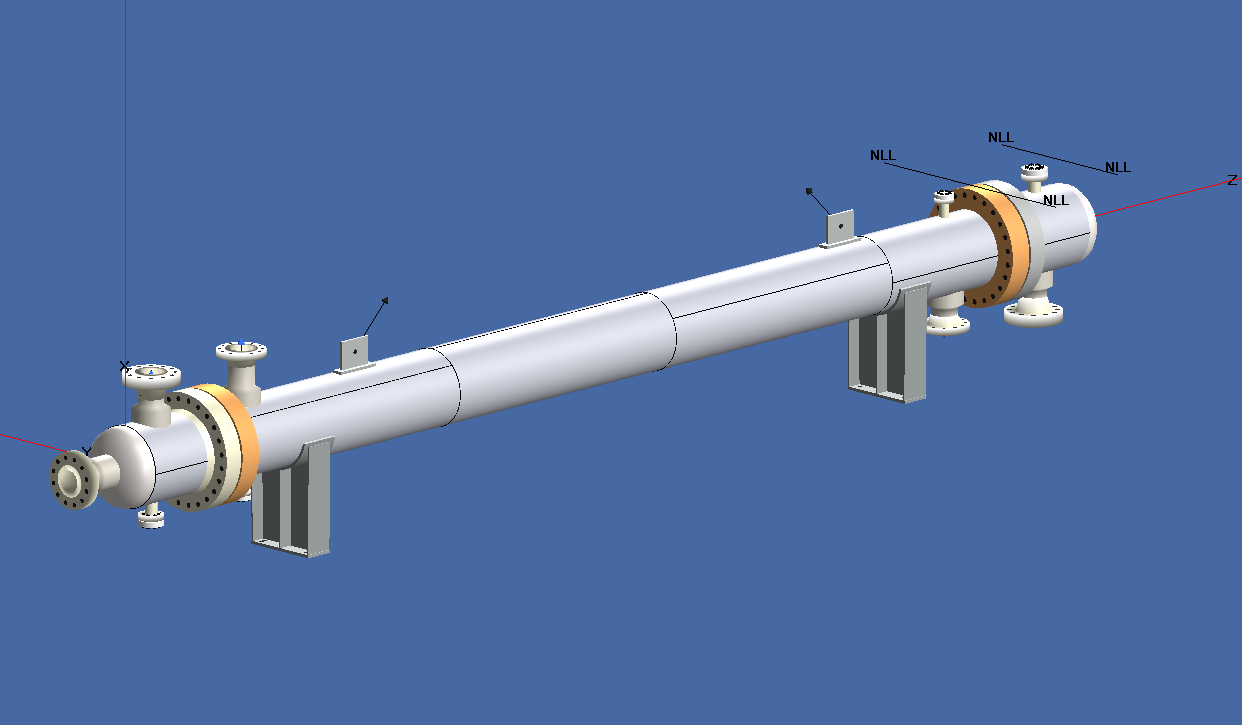

The heat exchanger is a piece of thermal heat transfer equipment that exchanges the thermal energy from one source, transferring it to another at a different temperature. In most heat exchanger designs, the fluids or gases used to transfer the heat are separated and dot mix, relying on the conductive nature of the manufacturing materials to transfer the energy from one to the other. Because of the wide variety of heat transfer applications, design effectiveness depends on temperature, pressure, fluid properties, viscosity, heat loss and thermal performance.

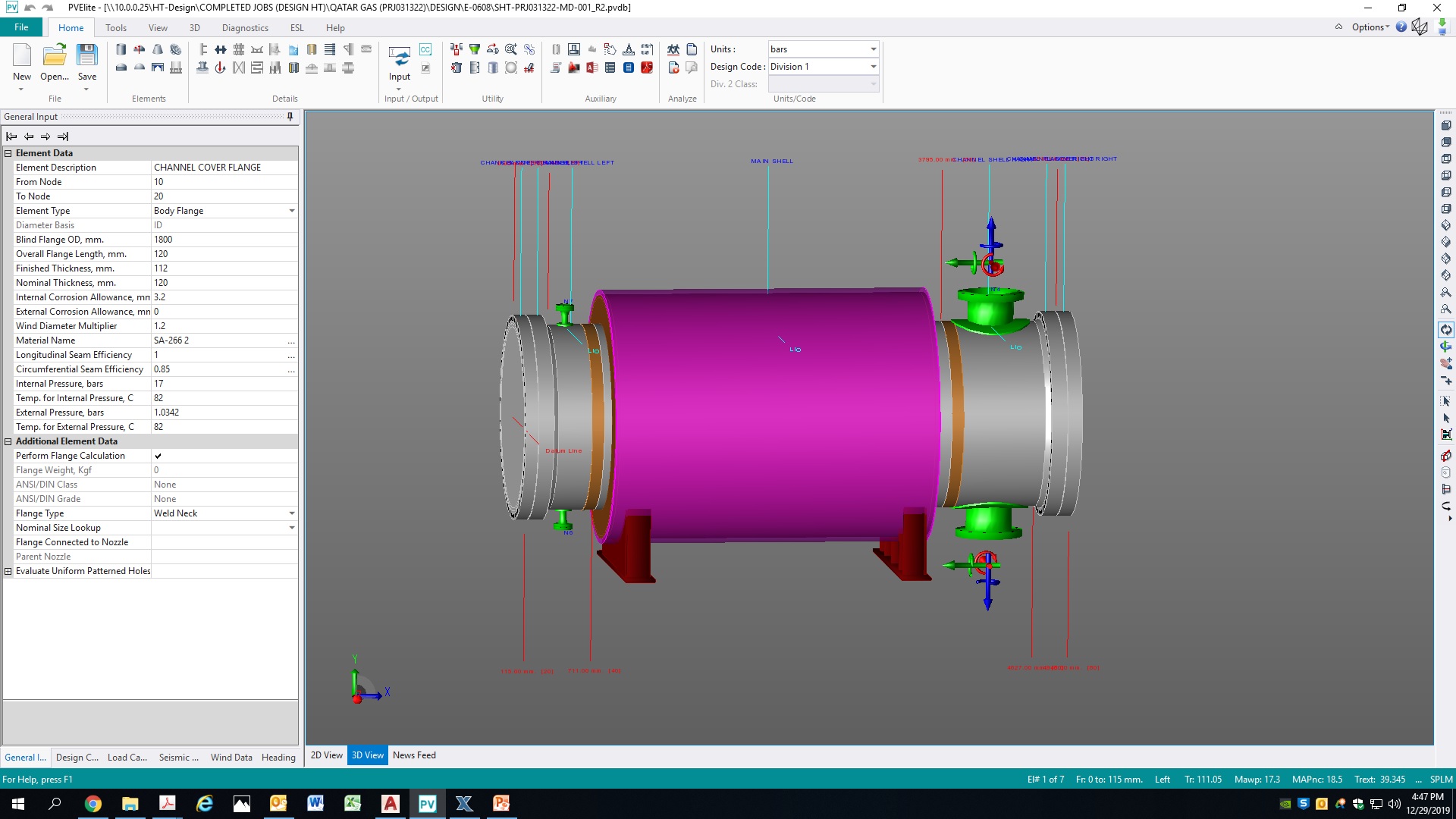

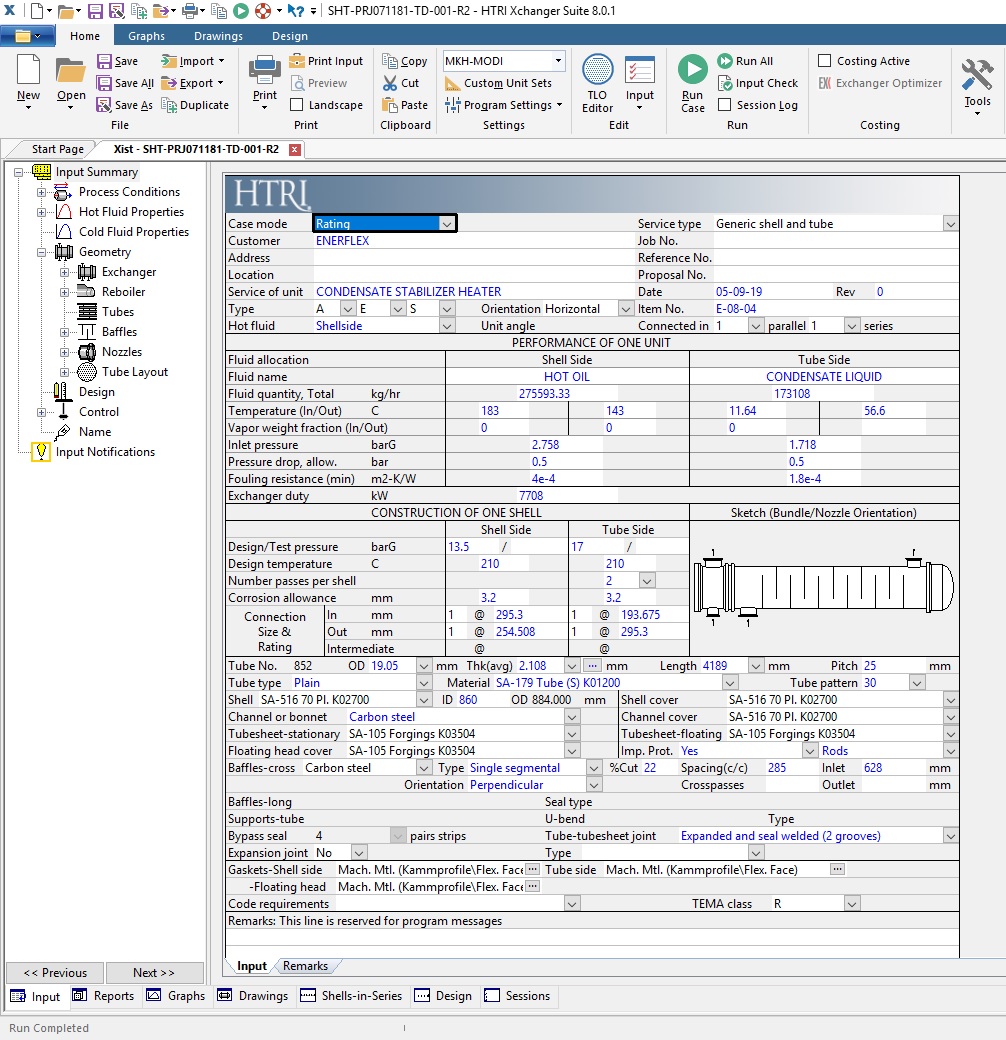

Serck has a history of delivering high-quality projects with innovative design solutions through our many years of expertise in heat exchanger manufacturing and service. Our team of skilled and highly experienced design engineers use the latest in HTRI, PV Elite, Compress and ASPEN software to design new exchangers, or solve performance challenges with existing equipment. This means our clients enjoy improved thermal efficiency, greater reliability, and improved ease of serviceability.

Our design team is able to provide first-class thermal and mechanical design services to our clients in a wide range of materials including (but not limited to) carbon steel, low alloy steel, stainless steel, duplex, super duplex, hyper duplex, copper nickel (70/30, 90/10) and copper aluminum.

We are also able to design and manufacture in nickel & molybdenum content materials, Monel, Inconel, Hastelloy as well as titanium & titanium base alloys.

Serck delivers a high-quality, cost-effective engineering design service which will quickly increase your operational performance and reduce operational costs, with projects delivered on-time and on-budget.

Contact us today to discuss your heat exchanger design needs.